For startups, family farms, and regional fertilizer producers, understanding the small scale fertilizer production line cost is a key step before entering the organic or biofertilizer market. Compared with large industrial plants, small fertilizer production lines require lower investment, simpler operation, and faster returns, making them ideal for price-sensitive buyers and first-time investors.

What Is a Small Scale Fertilizer Production Line?

A small scale fertilizer plant usually refers to a system with a capacity of 1–5 tons per hour, designed to produce powdered organic fertilizer or basic fertilizer granules. These compact fertilizer manufacturing lines focus on essential processing steps while avoiding unnecessary complexity.

Depending on the final product, it can also be called a mini fertilizer production line, low-cost fertilizer processing plant, or small fertilizer manufacturing setup.

Typical Equipment Configuration

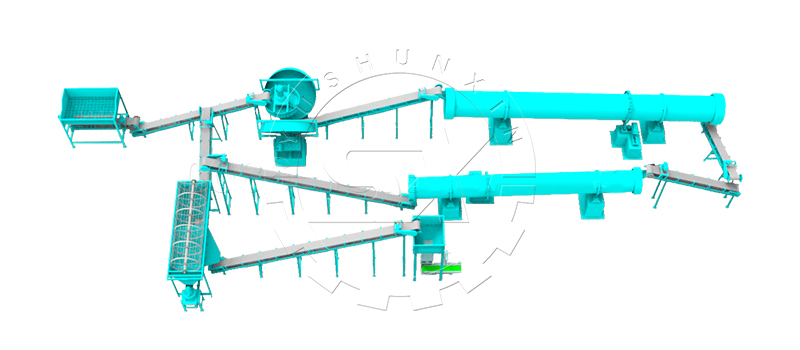

To control investment cost, a small fertilizer production line uses only core machines, including:

- Composting equipment (windrow compost turner or small groove compost turner)

- Crusher for fermented organic materials

- Mixer to ensure uniform nutrient blending

- Granulation machine (optional, for pellet fertilizer production)

- Screening machine for particle size control

- Packing machine for final product packaging

For powdered fertilizer, granulators and dryers can be omitted, significantly reducing the small fertilizer plant investment cost. Learn more!

How Much Does a Small Fertilizer Production Line Cost?

In general, the cost of a small scale fertilizer production line ranges from USD 30,000 to USD 100,000, depending on configuration and automation level.

- Powder fertilizer line: USD 30,000–50,000

- Basic granulation line: USD 60,000–100,000

Factors affecting price include raw material type, output capacity, granulation method, and labor cost optimization.

Why Small Fertilizer Lines Are Ideal for Price-Sensitive Buyers

Small fertilizer production systems are designed for flexibility. They require less land, lower energy consumption, and minimal manpower. This makes them suitable for:

- Agricultural cooperatives

- Organic fertilizer startups

- Local fertilizer brands

- Developing markets with limited capital

Moreover, modular design allows future expansion without replacing the entire fertilizer production system.

Powder vs Granular: Which Is More Cost-Effective?

For budget-limited users, powdered organic fertilizer production is often the best entry option. Granular fertilizer production, while more expensive, offers better market acceptance and higher unit profit.

Choosing the right configuration helps investors balance fertilizer production cost, product form, and target market demand. Welcome to consult YUSHUNXIN!

Final Thoughts

A small scale fertilizer production line is not about cutting corners—it’s about smart investment. With proper equipment selection and process design, low-cost fertilizer manufacturing can still deliver stable quality and competitive returns.

For those looking to enter the fertilizer industry with limited capital, a small fertilizer production line offers the most practical and scalable solution. If you need a business plan, welcome to visit: https://www.fertilizerequipmentprice.com/small-scale-fertilizer-production-line/

No Responses