In today’s sustainable agriculture landscape, the organic fertilizer fermentation tank has become a vital piece of equipment for transforming agricultural and food waste into high-value compost. Unlike traditional open-air composting, which can be slow and inconsistent, modern fermentation tanks integrate advanced engineering and automation to achieve efficient large scale fertilizer decomposition. Below are five key technologies driving this innovation.

Automatic In-Vessel Compostor Systems

The heart of most modern setups is the automatic in-vessel compostor. This closed system provides precise control over temperature, humidity, oxygen levels, and microbial activity. Automation ensures that the organic materials decompose evenly and hygienically, drastically reducing labor costs and processing time. With sensors and smart controls, operators can monitor parameters remotely and make real-time adjustments, ensuring consistent compost quality.

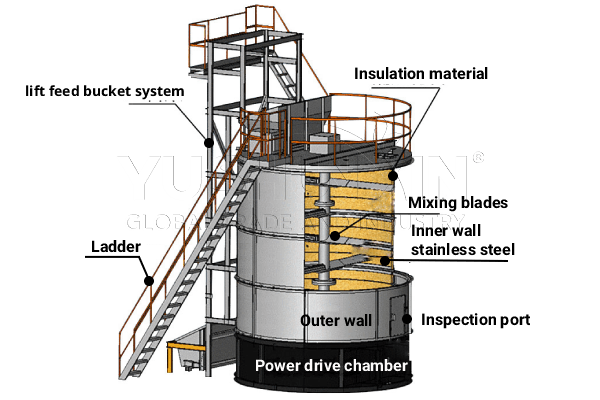

Vertical Fermentation Pot Design

Another breakthrough is the vertical fermentation pot design, which optimizes space utilization and enhances material flow. Vertical geometry allows the waste to move in a continuous downward pathway as fermentation progresses, ensuring full contact between microbes and materials at each stage. This design also facilitates better heat distribution and aeration, accelerating decomposition while requiring less ground area—perfect for urban farms or facilities with limited space.

Intelligent Temperature and Aeration Control

Temperature management is critical for achieving sterilization and promoting thermophilic bacteria activity. Advanced tanks employ intelligent aeration systems that deliver air uniformly to the compost mass, automatically adjusting airflow based on temperature feedback. This not only shortens fermentation time but also minimizes odor emission and energy waste.

Energy Recovery and Emission Reduction Technology

Modern fermentation tanks often include heat recovery mechanisms and gas collection systems. The heat generated during decomposition can be recycled to maintain optimal fermentation temperatures or used elsewhere in the production process. Meanwhile, emissions of ammonia and carbon dioxide are captured or bio-filtered, ensuring the process remains environmentally friendly.

Integrated Post-Treatment and Drying Units

After fermentation, the compost still contains moisture and may need further stabilization. Integrated drying and screening components complete the transformation process within the same system. This integration reduces handling and contamination risks while improving final product consistency and appearance.

In summary, today’s organic fertilizer fermentation tank is far more than a simple container—it’s a sophisticated biotechnological system designed for efficiency, sustainability, and scalability. By combining automatic in-vessel compostor systems, vertical fermentation pot design, intelligent control, and energy recovery, these technologies are redefining how the world manages large scale fertilizer decomposition. Farmers, recyclers, and eco-industries worldwide are adopting these innovations to close the loop between waste and resources, contributing to a cleaner and more sustainable planet. If you are interested in the project, you can visit https://fertilizerequipmentmanufacturer.com/vertical-fermentation-pot/

No Responses