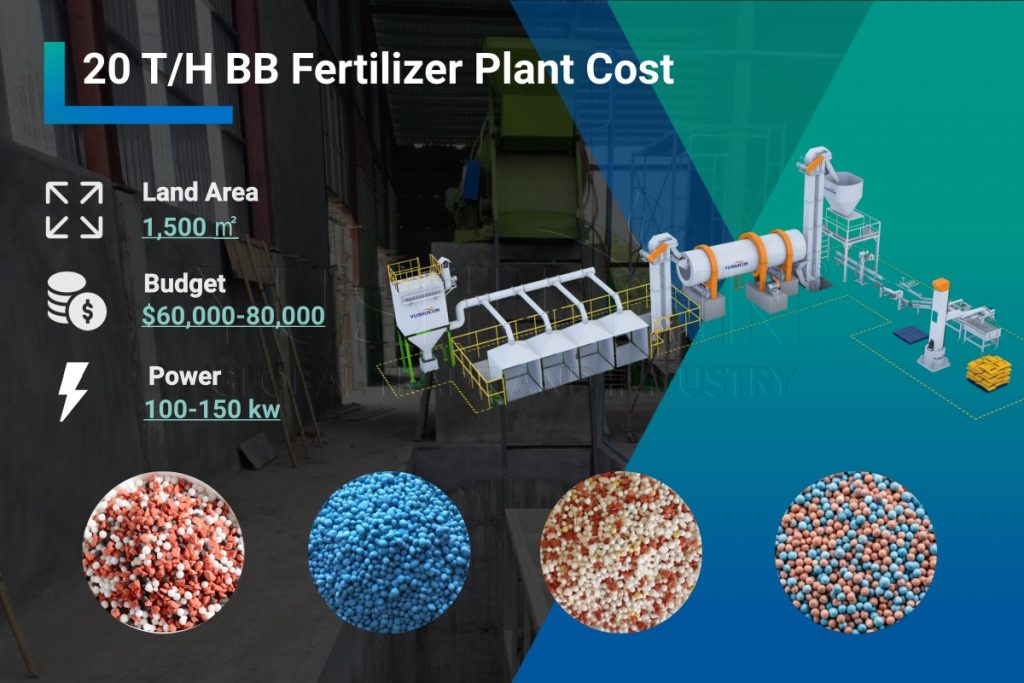

A complete 20 tons per hour bulk blending fertilizer production line usually targets stable output, flexible formulas, and controlled operating cost, so the core discussion always returns to price, budget planning, and fertilizer plant setup details. In most market quotations, a standard BB fertilizer plant for 20 t/h bulk blend fertilizer production often falls into a USD 60,000–80,000 equipment budget range, although the final price depends on batching accuracy, blending uniformity, dust control options, and packing configuration. In addition, a typical fertilizer production plant needs about 1,500 m² of workshop and storage space, 6–8 workers, and a total installed power around 100–150 kW/h. Therefore, a buyer who plans to build or establish a fertilizer plant needs to evaluate both machinery cost and operating conditions, especially around the blending/mixing process that defines bulk blended fertilizer quality.

What raw materials can support stable BB fertilizer production and NPK blending preparation?

A 20 t/h BB fertilizer production line usually works best with dry, free-flowing granules because bulk blending relies on proportioning and mixing, not chemical granulation. Suitable raw materials for bulk blend fertilizer manufacturing include urea (46% N), ammonium sulfate, ammonium chloride, DAP (18-46-0), MAP (11-52-0), MOP/potassium chloride (0-0-60), SOP/potassium sulfate (0-0-50), and granular limestone or dolomite as conditioner options. In many NPK blending and NPK mixing procedures, buyers also include granular micronutrients such as boron, zinc sulfate granules, magnesium sulfate granules, and iron chelate granules, because the bulk blended process allows fast formula switching. Meanwhile, a fertilizer manufacturing plant cost model should include raw material constraints, because wide particle size differences often reduce blending uniformity and increase rework cost, so raw material screening standards usually protect the 20 t/h BB fertilizer plant budget.

How does the blending process define the equipment list and the fertilizer plant setup cost for 20 t/h?

A 20 t/h bulk blending fertilizer production procedure normally follows “storage → batching → conveying → blending/mixing → packing,” and each step influences the fertilizer plant setup price and the operating budget. Many fertilizer factories choose an automatic/static batching machine because accurate dosing directly supports NPK blended fertilizer consistency and reduces formula loss. A bucket elevator often handles gentle conveying, so granules keep shape and dust stays manageable during bulk blend fertilizer production. The core machine typically uses a drum type BB fertilizer mixer for large capacity, because the rotating drum supports continuous NPK mixing and stable discharge; small-capacity plants often choose a smaller BB fertilizer blender/mixer, but a 20 t/h target usually needs the drum blender. A packing machine with weighing control often finishes the BB fertilizer making process and supports trade-ready delivery. In some cases, a crushing machine (vertical crusher or chain crusher) supports raw material size adjustment for off-size granules, and this option changes the quotation because it adds power, structure, and maintenance cost.

What total price and budget details usually apply to a complete 20 t/h bulk blend fertilizer production line quotation?

A buyer who requests an equipment quotation for a complete 20 t/h bulk blending fertilizer production line usually receives an average machine price range of USD 60,000–80,000, and this figure commonly covers batching equipment, conveying machinery, a drum type BB fertilizer blender, and a packing system. However, a complete fertilizer plant cost evaluation also includes site and utilities, so a realistic budget discussion covers 1,500 m² land/workshop planning, material storage bays, and truck lanes that support high-throughput bulk blend fertilizer manufacturing. A 20 t/h BB fertilizer factory commonly runs with 6–8 employees, because one team often covers loader feeding, batching supervision, mixer monitoring, bagging, and forklift handling. A typical total power range of 100–150 kW/h also affects operating cost, especially when conveyors, elevators, and dust collection fans run together. Therefore, an accurate fertilizer production plant cost plan normally separates “equipment price” from “installation, wiring, steel structure, and civil works,” because those items vary by region and directly influence the final BB fertilizer plant budget.

How much granular material purchasing supports 20 t/h NPK blending, and how does raw material cost affect total production cost?

Raw material purchasing quantity usually follows the target formula, and a 20 t/h bulk blend fertilizer production target requires 20 tons of total granules per hour entering the batching and NPK mixing system. For example, an NPK 15-15-15 bulk blended fertilizer recipe could use DAP for P, urea for N, and MOP for K, and a typical hourly purchasing/consumption plan can follow the nutrient balance principle: about 6.5 t/h DAP, 5.1 t/h urea, and 5.0 t/h MOP, while about 3.4 t/h filler/conditioner granules (such as limestone granules or other compatible bulk materials) closes the mass balance to 20 t/h. Another example, an NPK 20-10-10 NPK blended fertilizer production plan may use roughly 4.3 t/h DAP, 7.1 t/h urea, 1.7 t/h MOP, plus 6.9 t/h filler. These examples show why fertilizer factory cost control depends on stable supply and uniform granule size, because off-spec granules raise mixing segregation risk and increase repacking and re-blending cost during bulk blending fertilizer making.

Summary

A buyer who compares bulk blending fertilizer production line quotations usually achieves better decisions by matching the 20 t/h output target with batching accuracy, drum blending stability, and packing automation level, because these factors directly influence the final BB fertilizer plant budget and ongoing operating cost. A complete fertilizer production plant often fits USD 60,000–80,000 for the main machinery, while the full fertilizer plant setup cost also depends on 1,500 m² space planning, 6–8 staffing, and 100–150 kW/h power arrangement. A serious supplier comparison also checks raw material adaptability for bulk blend fertilizer production, because urea, DAP, MOP, SOP, and micronutrient granules need consistent size to support reliable NPK blending and NPK mixing performance. For buyers who want a detailed configuration list and a transaction-ready quotation based on local voltage, bag size, and formula range, a professional fertilizer equipment manufacturer- Yushunxin can provide a suitable reference plan. You can visit: https://www.fertilizerproductequipment.com/cost-to-build-a-20-t-h-npk-mixing-factory/

No Responses